Strengthen the safety of workplaces that process crystalline silica substances (CSS)

Winston Churchill once said, “Success is not final, Failure is not fatal: it is the courage to continue that counts” and James Clear, author of the book Atomic Habits, has said many things about continuous effort, including that it is a daily battle and that small improvements add up over time.

Maintaining safety habits demands ongoing effort to safeguard the workforce by staying compliant with changes in safety regulations.

You may be aware or not aware but as of September 1, 2024, new regulations came into effect to strengthen the safety of workplaces that process crystalline silica substances (CSS). These regulations apply to all materials that contain at least 1% crystalline silica, including engineered stone.

What are the new regulations?

- Businesses must assess if processing CSS will be high risk.

- If processing is high risk, businesses must put in place additional controls and a risk control plan.

- Businesses may need to monitor air quality and/or health of workers.

- Businesses must notify the regulator if they process legacy engineered stone.

Why are these regulations important?

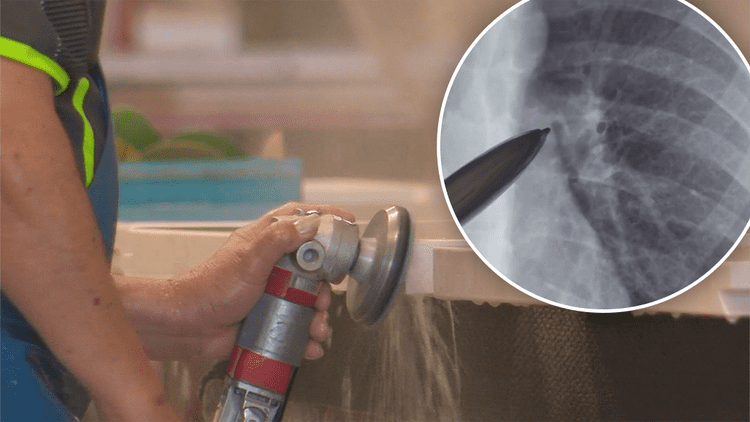

Breathing in crystalline silica dust can cause silicosis, a disease that can be disabling or fatal. The build-up of scar tissue eventually reduces the exchange of oxygen in the lungs and causes shortness of breath that progressively worsens.

Other symptoms of silicosis can include chest pain and a harsh, dry cough that may produce blood. There is no cure for silicosis.

What can businesses do to comply?

- Assess the risk of silica dust in their workplace.

- Implement control measures to reduce exposure to silica dust.

- Monitor air quality if there is a risk of silica dust.

- Train workers about the risks of silica dust and how to stay safe.

- Monitor the health of workers who are exposed to silica dust.

What are some high-risk activities that involve silica dust?

- Cutting, grinding, or polishing natural and engineered stone

- Excavation, earth moving, and drilling

- Clay and stone processing

- Paving and surfacing

- Mining, quarrying, and mineral ore treating

Stay Compliant with Mandatory Silica Education

With the enforcement of stricter regulations on crystalline silica in Australia, it’s imperative for professionals in construction and related industries to obtain appropriate training. At Newcastle Rescue & Consultancy Pty Ltd (RTO 41033), we provide comprehensive courses designed to meet these regulatory requirements and enhance workplace safety.

Our Specialized Silica Training Courses (Face to Face or MS Teams online):

1. Silica Awareness Training:

- Course Overview: This course educates participants on the health hazards associated with crystalline silica exposure and the necessary precautions to mitigate these risks.

Key Topics:

- Identification of materials containing silica

- Health effects of silica dust

- Implementation of control measures

- Proper use of personal protective equipment (PPE)

- Who Should Attend: Workers and supervisors involved in tasks that may expose them to silica dust, such as cutting, grinding, or drilling materials like concrete, bricks, or stone.

2. CPCSIL3001 – Work with Products and Materials Containing Crystalline Silica:

- Course Overview: This unit provides participants with the skills and knowledge required to work safely with products and materials containing crystalline silica.

Key Topics:

- Planning and preparing for work with silica-containing materials

- Selecting and using appropriate tools and equipment

- Applying safe work practices to minimize exposure

- Conducting clean-up and decontamination procedures

- Who Should Attend: Tradespeople and construction workers who handle materials such as engineered stone, concrete, or tiles.

3. CPCSIL4001 – Supervise and manage work with products and materials generating respirable crystalline silica

- Course Overview:

Key Topics:

- Plan and prepare for work.

- Conduct workplace briefings and consultations.

- Implement safety requirements.

- Manage worksite operations.

- Oversee compliant clean-up, maintenance and storage

operations. - Review workplace operations.

- Who Should Attend: The unit is suitable for persons conducting a business or undertaking (PCBU), employers, supervisors

and managers responsible for ensuring the health and safety of employees, contractors and subcontractors

and suppliers when working with products and materials containing CS.

Why Choose Newcastle Rescue & Consultancy Pty Ltd?

- Expert Trainers: Our instructors possess extensive industry experience and are well-versed in current regulations and best practices.

- Flexible Delivery: We offer training sessions at our state-of-the-art facilities in Beresfield, NSW, or can arrange on-site training to accommodate your team’s needs. We can deliver online via MS Teams which can assist delivery for multiple and remote sites.

- National Accreditation: As a Registered Training Organisation (RTO 41033), our courses meet national standards, ensuring you receive recognized and respected certifications.

Enrol Today:

Don’t wait until it’s too late. Ensure your team is trained, compliant, and safe. Contact us at 1300 356 686 or email enquiries@newcastlerescue.com.au to register for our upcoming courses.

Stay ahead of regulatory changes and prioritize safety with Newcastle Rescue & Consultancy Pty Ltd.